|

|

|

|

|

|

|

click the image

for the presentation |

GEARBOX DESIGN

The choices of the gear ratios and of the final drive ratio are

fundamental to make the most of the engine power, but are also

the most difficult to perform, in fact depend from the

characteristics of the engine, of the vehicle, and from the

weather and the grip conditions . Thanks to the software Gearbox

Design you can take into account of all these aspects and easily

find the best gear ratios for your specific case, moreover you

can identify the optimal upshift engine speed, and study the

inertia of the engine that allows you to improve further the

performance. |

|

|

|

|

How it works?

|

The software

Gearbox Design allows to see how the choices of the gear ratios affect the performance of the vehicle

(speed, acceleration, etc.) in function of the engine power curve, allowing you therefore to find with ease the

best solutions for your needs.

|

To be able to make the best choices is necessary that the

calculation is very precise, for this reason

the software Gearbox Design

takes into account of all the factors that influence the

performance. |

| - vehicle weight |

- wheels axle inertia |

| - aerodynamic drag |

- weather conditions |

| - rolling resistance |

- vehicle balance |

| - engine inertia |

- grip level |

| - gearbox inertia |

|

|

In addition to this the software Gearbox Design

allows you to manage the upshift engine speed and the time duration

of the gear shift, that can change in function of the gearbox

model, or for the ability of the driver, and that they also

influence the performance and therefore the choices to be made.

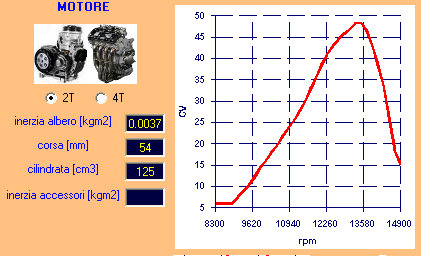

The operation of the software is very simple.

For first you must enter the data

of the engine power curve. The power curve can be

measured with dynotest, or can

be calculated directly from the

software Gearbox Design entering the data acquired

from your acquisition system in a session on track.

Together to this you must enter some

features of the engine (type, stroke, displacement),

and if you know them, the values of the

crankshaft inertia, and of eventuals

auxiliaries (flywheel,

ignition system, clutch). |

|

|

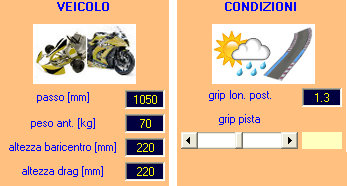

You must then enter the informations

of the vehicle, and of the driving wheels. In

addition to the total weight of the vehicle with driver,

must be inserted, the frontal area, and the diameter of the

wheels. The values of aerodynamic drag, of the rolling

resistance, and of the wheels inertia, if aren't known can be derived from the examples present in the software for all the main competition vehicles (kart,

motorbike, cross,

motard, car, etc.) |

|

|

These data are sufficient to perform the calculation

assuming that the adherence allows to exploit all the engine

power, but the software Gearbox Design

allows also to perform the calculation taking account of the

real adherence avalaible, in this way you can make

the choices of the gear ratios also on the basis of this

important factor. It will be enough

enter in the software also the data relatives to the gravity

of the vehicle, and to the grip level. |

|

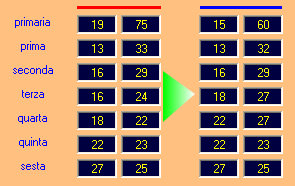

At the end you must simply enter

the gear ratios, and the final drive ratio, that you

want test. In addition to this the software

allows you to indicate the engine speed where you want make

the upshift gear.

At this point you can perform the calculation to

see the performance, and to test new solutions to have

improvements for your needs. |

|

|

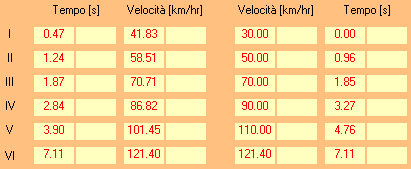

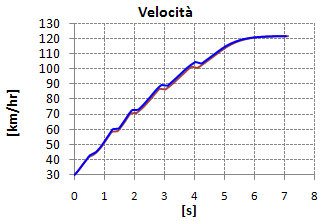

Risultati |

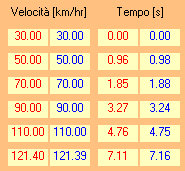

| At

the end of the calculation the software Gearbox Design shows

you the maximum

speed reached in each gear, and the time taken to reach it.

Moreover shows you the time necessary

to reach the differents speed. In this way you will

have a complete picture, of the

choices made, and when you compare the different

solutions to be tested. |

|

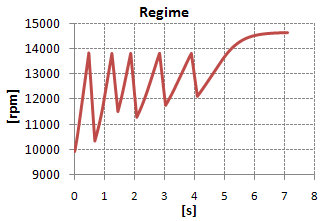

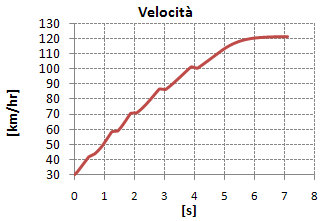

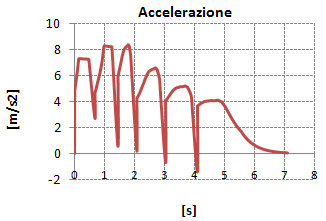

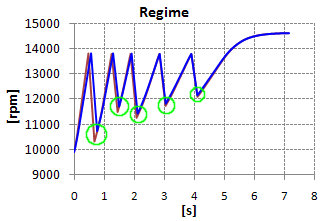

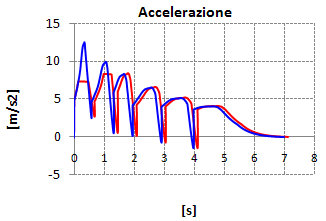

| In addition to

the global data, the software shows you the

graphs in

function of the time of all the of all the quantities of

main interest to evaluate the performance, therefore

the progress of the engine speed,

of the speed, and of the

acceleration, in the differents

gears shift. This allows you to

evaluate the

performance in all its phases, allowing you to evaluate in

the detail the most appropriate choices for each gear. |

|

|

|

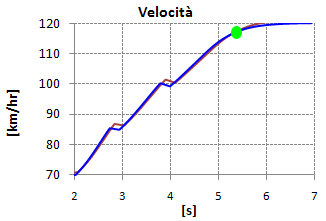

| OPTIMAL GEAR RATIOS |

The software Gearbox Design allows to

find the optimal gear ratios,

infact allows to compare the performance with the differents

solutions, and therefore to find

easily that more adapted at your needs.

For example in the case shown the new gear ratios (blue)

allow to have a better performance until to 115 km/hr, so in

the tracks where you stay little time above this speed, the

solution found is certainly improving. Just to make people

understand the importance of the gear ratios,

in the case

shown you earn 2-3 cents each acceleration, it seems little,

but in a track with 10 corners, they are 2-3 tenths a lap,

which makes a big difference to win. |

|

|

|

| OPTIMAL FINAL DRIVE RATIO |

|

In addition to the choice of the gear ratios, another aspect

very important is the choice of the

final drive ratio,

especially from track to track. The software Gearbox Design

allows you to see how changes the performance in function of

the final drive ratio, so you can

know based on

the different final ratios, which choice can be best for the

different situations. |

|

|

|

|

In the case shown, for the characteristics of this engine

the change of the final ratio leads to a substantial gain,

but at the expense of the maximum speed, so thanks to this

information will be

easy to make

the right choice based on the characteristics of the track. |

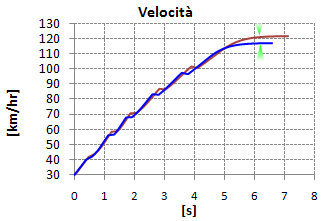

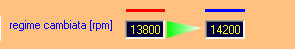

| OPTIMAL UPSHIFT ENGINE SPEED |

|

An other aspect very important, above all for the two stroke

engines, is that to trovare find the

engine speed where is better to make the gear upshift to

have the maximum acceleration, the

software Gearbox Analysis in function of the characteristics

of your engine allows you to identify this value, and then

to advise the

driver with certainty how to manage the gear upshift to be

faster. |

|

|

|

|

In the case shown, delaying the gear upshift leads to

improved performance,

however,

everything is linked to the characteristics of the engine,

and which is the optimal value must be evalueted case by

case, thanks to the software Gearbox Design you can

make the best choice specific for your

engine and for your vehicle. |

| OPTIMAL ENGINE INERTIA |

|

A factor that

has become increasingly important in the competitions is the

engine inertia, in fact for many years has been tried

to reduce to the maximum the inertia to gain in

acceleration, after has been understood that this also has

counterproductive effects, so is necessary

to find the optimal compromise. In fact the inertia

can be used to smooth the engine

with high torque, and this can be useful for example for the

motorbike, or in the cross, or can

improve the upshift gear, and this is very important

in the two stroke engines, as for example in the kart. The

software Gearbox Design allows you to compare differents

solutions as you can easily see how the performance changes

and which

advantages each solution can bring compared to the other. |

|

|

|

|

In the case shown, you can see that for these engine and

vehicle, increasing the inertia brings a deterioration in

performance until to 70-80 km/hr, after there is an

advantage, moreover you can see that there is a lower

decrease of the engine speed in the gear shift to the

advantage of the fluidity of driving. |

Obviously every engine and every vehicle require differents choices,

for this reason the help of the software Gearbox Design is essential, and allows you to find the

best solutions to make the most of the

different power curves, but also to

better meet the different needs that there are in function of

the competition (kart, motorbike, cross, motard, car, etc.), or of the

driving style of the driver.

Just to make understand again better how the optimal choice

depends from many factors, we show you

how changes the performance assuming

full adherence respect to consider the adehrence that really

the vehicle can give. You can see how in the

reality the acceleration that the engine can give in

function of its power, is limited in function of the grip

level of the track, and in function of the features of the

vehicle (weight, balance, wheel driving axle), therefore

without to take account of these factors, you risk to make

wrong choices with gear ratios that instead to improve the

acceleration, for example increase the wheels slipping

making driving more difficult, wearing and overheating the

tires. |

|

Instead, thanks

to the software Gearbox Design you can fully consider this

aspect and to make the choices, of the gear ratios, of the

final drive ratio, but also of the upshift engine speed, and of

the engine inertia, taking into account everything that

affects the performance, and then to find the solutions to

be really faster on the track.

|

|

| |

Purchase |

|

|

|

|

NT-PROJECT - Ferrara (Italy)

- info@ntproject.com |

tutto il

materiale contenuto nel presente sito è coperto dalle leggi sul diritto d'autore ©

2005/19 |

|