In practice usually the tuners have directly the head to be worked and not

have available the three-dimensional drawings of intake and exhaust ducts

to study them through CFD simulations, for this the software

Head Design was designed to recreate the main geometry

main of the

duct through simple workshop measurements , which can

be made directly on the head, or creating the mold of the

duct and measuring it.

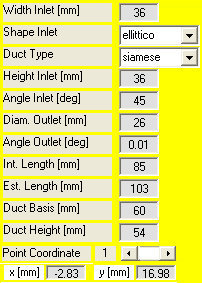

Thanks to simple measures it is possible

to insert

easily in the software the geometric characteristics of the section

main of the duct, of the valve guide and of the

valve.

For what concerns the geometry of the main section

of the

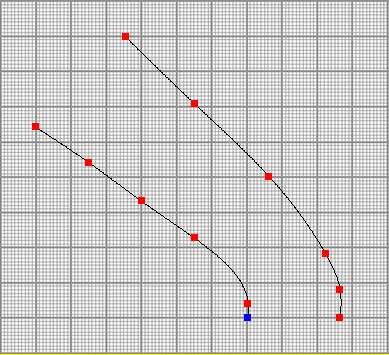

head ducts in the software there is a millimeter area with

two spline curves that allow to define the shape of the

internal and external profiles of the duct simply

dragging control points and seeing in real time

how to edit the curve. The coordinates of the points of

control can also be entered manually, then

measuring, the mold of the duct, or some key dimensions

of the duct in the engine head, you can easily recreate the

geometry to study and optimize with the software. |

|

|

|

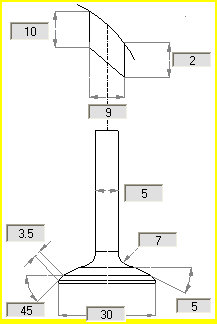

After entering the required data, you can see the

geometry that has been recreated for the duct, the guide

valve and valve.

This geometry is aimed at identifying the main geometries characteristics

of the duct in terms of lengths,

curvatures and impediments, in order to make a

calculation on the fluid-dynamic basis of the main factors that

determine the losses during the flow passage

through the duct. |

|

After displaying the inserted geometry, you can proceed to the

calculation. The software performs a flowbench simulation of the

duct and determines, through appropriate fluid dynamics calculations,

the losses that will occur through the duct at the passage of the

flow.

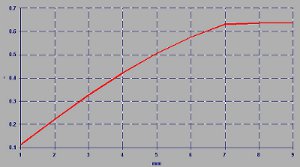

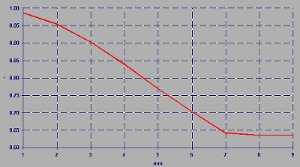

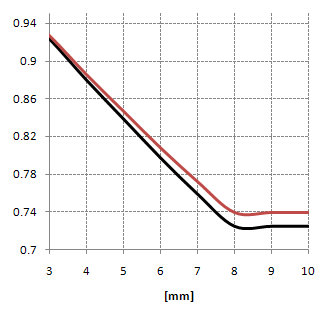

At the end of the calculation the software shows as a function of the lift

valve the following quantities:

| TOTAL DISCHARGE COEFFICIENT |

| FLUID DYNAMIC DISCHARGE COEFFICIENT |

| FLOW RATE |

| GEOMETRIC AREA |

| EFFECTIVE AREA |

| AVERAGE GEOMETRIC AREA |

| AVERAGE EFFECTIVE AREA |

Thanks to the calculated quantities you can have a

clear picture of the characteristics of the duct, both in terms of

passage areas, both for what concerns pressure

and flowrate losses that will occur for the flow.

These results will be the reference to study

through the software the geometric changes that

allow you to optimize the duct to reduce fluid dynamics losses and increase the flowrate at all advantage

of the engine performance. |

| TOTAL DISCHARGE COEFFICIENT |

|

| FLUID DYNAMIC DISCHARGE COEFFICIENT |

|

|

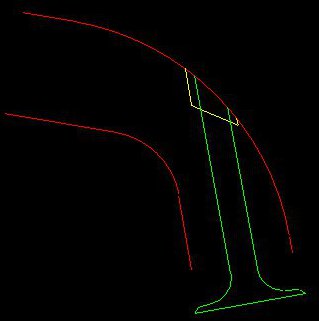

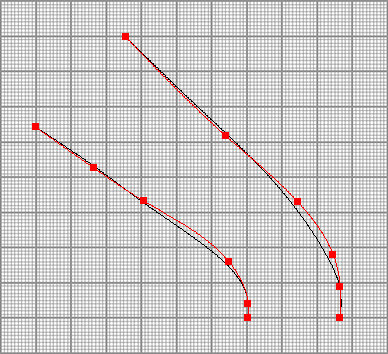

In fact, after the calculation on the initial geometry will be possible to simulate the geometric changes that

you intend to make on the duct and verify if they will be improving or

less. This will allow you to find the correct direction first

to proceed with the realization , thus avoiding many

practical attempts before to reach the desired solution.

This phase in the software is very simple, in fact in a specific zone is shown a millimeter area, with drawn the

initial geometry in black, which can be easily changed

simply by moving the points of control and seeing in red the

new geometry.

|

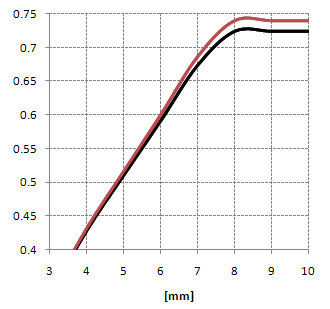

After entering the

changes to be made on the duct will be sufficient

perform the calculation to see if the interventions hypothesized

actually bring improvements.

Based on the results it will be easy to understand the direction

of the interventions to be carried out, and then working with the software

will be possible to identify the changes that allow

to optimize the geometry. |

| TOTAL DISCHARGE COEFFICIENT |

FLUID DYNAMIC DISCHARGE COEFFICIENT |

|

|

|

The software Head Design is therefore a tool for all those who

they can not use CFD simulation, but that want to

equally have a help from the calculation to optimize at the best the engine head.

In fact, although the software works on a simplified geometry

characterizing the duct, it is able to seize the

main effects of the changes that you want to make and then

orientate the development in the best direction.

|