|

|

|

|

|

|

|

click on the image

for the presentation |

VARIATOR DESIGN

the features of the variator are fundmental

to obtain the maximum from the engine power, but are

also the most difficult to find, in fact the operation

of the variator depends from many elements , that must

to be coupled

adequately to get the continuous variation of the

transmission more effective for the engine and the vehicle. Thanks to the

software Variator Design you can see how changes the vehicle performance,

acting on all the elements that make up the variator,

so you can easily find the solution that lets you

get the maximum performance based on the characteristics of the

engine. |

|

|

|

|

How it works?

|

The software

Variator Design allows to see how the choices of the

various elements of the variator affect the performance of the vehicle

(speed, acceleration, etc.) in function of the engine power curve, allowing you therefore to find with ease the

best solutions for your needs.

|

To be able to make the best choices is necessary that the

calculation is very precise, for this reason

the software Variator Design

takes into account of all the factors that influence the

performance. |

| - vehicle weight |

- wheels axle inertia |

| - aerodynamic drag |

- weather conditions |

| - rolling resistance |

- vehicle balance |

| - engine inertia |

- grip level |

|

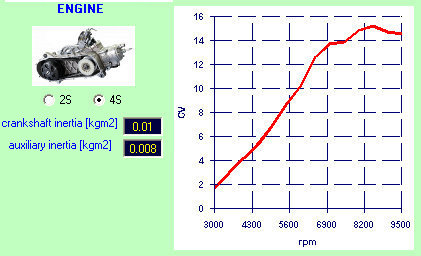

The operation of the software is very easy.

For first you must enter the data

of the engine power curve. The power curve can be

measured with dynotest, or can

be calculated directly from the

software Variator Design entering the data acquired

from your acquisition system in a session on track.

Together to this you must enter the

type of engine (2S or 4T),

and if you know them, the values of the

crankshaft inertia, and of the

auxiliaries mounted (pulley, flywheel,

ignition system, etc.).

|

|

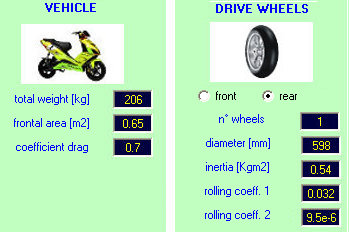

You must then enter the informations

of the vehicle, and of the driving wheels. In

addition to the total weight of the vehicle with rider,

must be inserted, the frontal area, and the diameter of the

wheels. The values of aerodynamic drag, of the rolling

resistance, and of the wheels inertia, if aren't known can be derived from the examples present in the software for all the main vehicles with variator (scooter,

quad, minicar, etc.)

|

|

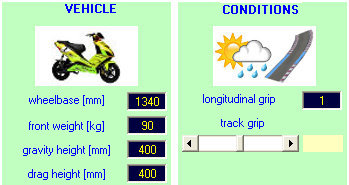

| These data are sufficient to perform the calculation

assuming that the adherence allows to exploit all the engine

power, but the software Variator Design

allows also to perform the calculation taking account of the

real adherence avalaible, in this way you can make

the choices of the gear ratios also on the basis of this

important factor. It will be enough

enter in the software also the data relatives to the gravity

of the vehicle, and to the grip level. |

|

| If between the variator and the wheel there is also a

fixed gear transmission, in the software is possible to

enter these gear ratios. Moreover in this area you can

enter, if you know it, the inertia of the shaft of the

clutch pulley. |

|

|

At this point you must enter the characteristics of the

variator, which can be modified until you find the optimal

solution to get the maximum performance from the vehicle and

fully exploit your engine. |

| The software

Variator Design allows to define easily all the features of

the variator that affect the operation, so will be possible

to act on each element to see how it affects the performance

and to find the best solution. |

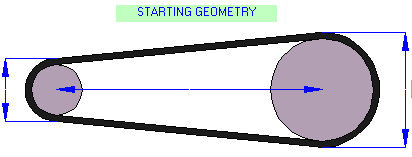

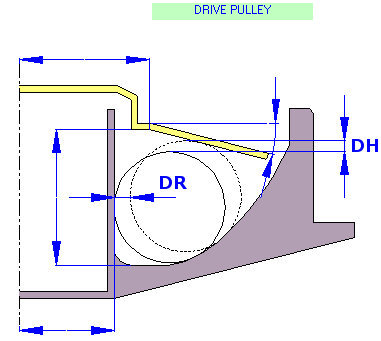

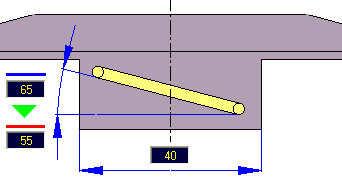

For first you must enter the standstill geometry of the

variator, therefore:

- starting diameter drive pulley

- starting diameter clutch pulley

- wheelbase pulleys |

|

After you must enter the geometry of the drive pulley:

- rollers scrolling position and profile

- fixed plate shape and angle

- distance plate semi-pulley

You must enter also the features of the belt:

- width

- angle |

|

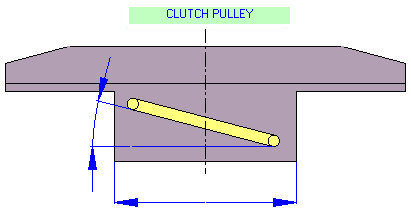

Moreover you must enter the characteristics of the

torque corrector on the clutch pulley:

- diameter helicoidal guide

- angle helicoidal guide |

|

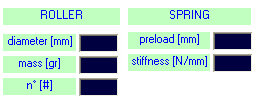

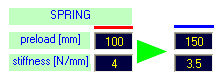

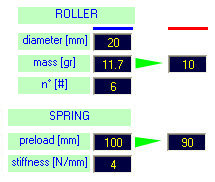

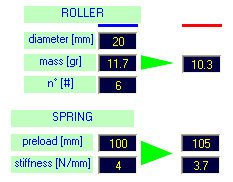

At this point you must enter the features of the

elements that you can easily modify on the variator, the

rollers, and the contrast spring.

| For the rollers: |

For the spring: |

- diameter

- weight

- number |

- preload

- stiffness

|

|

|

|

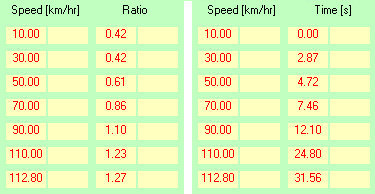

Results |

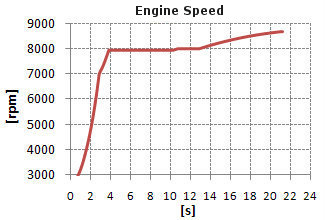

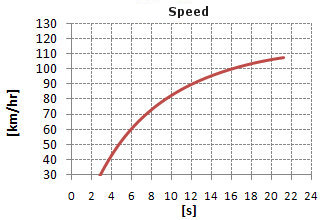

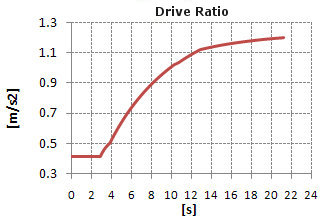

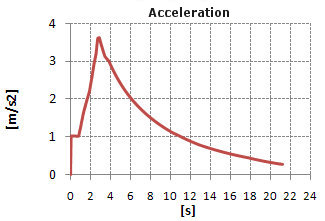

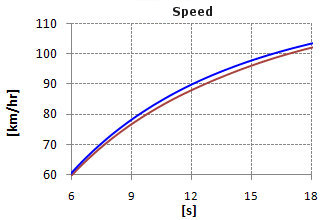

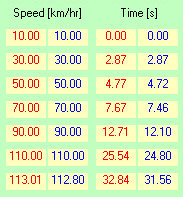

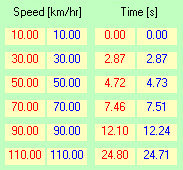

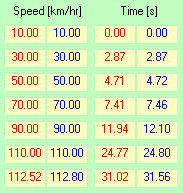

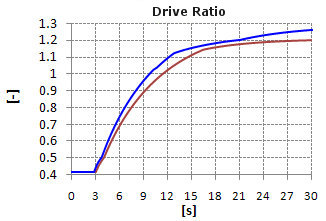

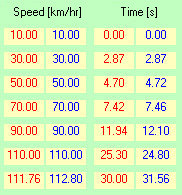

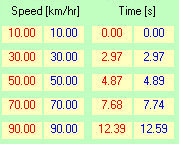

| At the end of the calculation the software Variator

Design you show how the variator changes the transmission ratio, and gives its value at the differents speed. Morevoer you show the time

to reach the differents speed. In this way

you can have a complete picture of the choices made, also

to compare the differents solutions that you want testing. |

|

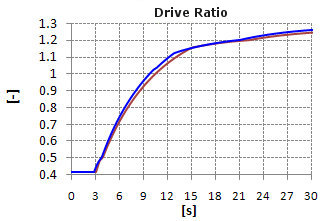

| In addition to

the global data, the software shows you the

graphs in

function of the time of all the of all the quantities of

main interest to evaluate the performance, therefore

the progress of the engine speed,

of the speed, and of the

acceleration,

in function of the time. Furthermore you show

how changes the transmission ratio during the acceleration. This allows you to evaluate the performance in all

the phases, being able to analyze in detail the

more suitable choices for the variator. |

|

|

|

|

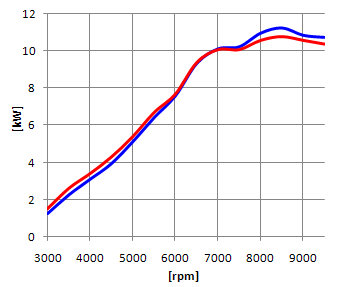

| OPTIMAL ROLLER |

The software Variator Design allows to find

the optimal weight of the variator rollers, in fact allows to

compare the performance with differents solutions, and therefore to

easily find the more adapted for your needs.

For the example in the case of the images, the new rollers (blue)

allow to have a better performance. In fact in

this case the maximum speed is reached with a time

significantly lower, and in general the whole phase of

acceleration is more competitive. |

|

|

|

|

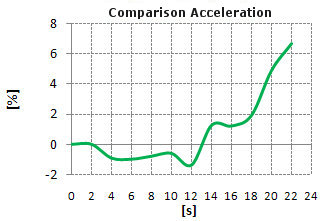

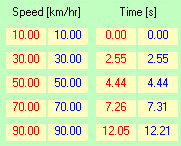

OPTIMAL PRELOAD and SPRING |

| Together to the choice of the rollers, other aspect

very important is the choice of the

contrast spring, and of the preload,

above all track by track. The software Variator Design allows

you to see how changes the performance in function of the spring features,

so you can know in base

at the different springs, which choice can be better for the

different situations. |

|

|

|

| In the case of the images, the new spring, and the new preload, given

a worsening of the acceleration

in the central phase, but after a consistent improvement, therefore

thanks at this information will be easy to make the best choice

in function of the features of the track. |

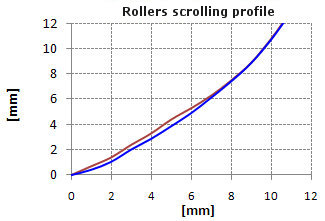

| OPTIMAL ROLLERS SCROLLING PROFILE |

|

In the examples shown above you have seen the use of the

software to obtain an optimal set-up of the variator, then

by intervening on the elements that are easy to replace, but

the software Variator Design can also be used during the

design of the variator, or to change radically the

characteristics of the variator, in fact it is possible to

study a different profile on which the rollers scroll. |

|

|

|

|

In the case of the images the new scrolling profile (red)

that gives a faster rise of the roller in the starting phase,

determines an improvement of the performance, all

however it is related to the characteristics of the engine, and what is the

optimal value must be assessed on a case-by-case basis,

thanks to the software Variator Design you can

make the best choice specific for your engine and your vehicle. |

| OPTIMAL TORQUE CORRECTOR |

|

As for the rollers scrolling profile, the choice of the

torque corrector characteristics significantly influences

the behavior of the variator. Thanks to the software

Variator Design also this aspect can be assessed easily and

safely. |

|

|

|

In the case shown, the new torque corrector (red) determines

a more homogeneous variation of the transmission ratio

during the acceleration phase, and this leads to an

improvement in performance up to almost the maximum speed.

Also from this example you can see how

thanks to the

software Variator Design is possible to find many solutions

for the variator, both in setup phase, both in design

and development phase, that allow to

improve the performance in function of your needs and

to exploit at the best your engine based on the

characteristics of the vehicle and its use.

|

| OPTIMAL SET-UP

FOR DIFFERENTS RIDER WEIGHT |

As we have seen according to the characteristics of the

engine and of the vehicle, thanks to the software Variator

Design, is possible to find the best solutions for the

variator to achieve the maximum performance, in addition to

this, the software can also be used to differentiate the

variator set-up in based on the weight of the rider, in

fact often happens to have riders of different weight, and

therefore is important to see if the choices made for the

variator are optimal for both riders, or it is necessary a

different setup.

|

|

|

|

|

In the case shown by intervening on the variator set-up, an

improvement compromise has been found which reduces the loss

of acceleration due to the greater weight of the rider. |

| OPTIMAL SET-UP

AFTER ENGINE TUNING |

|

If you make engine tuning that modifies the power curve of

the engine, the set-up and the characteristics of the

variator that had been identified as better, may require

modifications. Thanks to the software Variator Design, by

inserting the new power curve and working on the different

calibration elements of the variator, you can easily see if

there is a better solution than the previous one to make the

most of the new power curve. |

|

|

|

|

In the case shown, thanks to the software it is possible to

work on the variator set-up until finding a solution that

better adapts to the new power curve of the engine,

obtaining advantages on the performance of the vehicle. |

Obviously every engine and every vehicle require differents choices,

for this reason the help of the software

Variator Design is essential, and allows you to find the

best solutions to make the most of the

different power curves, but also to

better meet the different needs that there are in function of

the competition, at the track, or of the

driving style of the rider.

|

| |

Purchase |

|

|

|

|

NT-PROJECT - Ferrara (Italy)

- info@ntproject.com |

tutto il

materiale contenuto nel presente sito è coperto dalle leggi sul diritto d'autore ©

2005/19 |

|